WHY NOT CAST YOUR OWN?

Want to get more shooting for less money? Want an alternative to commercial ammunition that may suddenly increase in price or decrease in availability? Want to become a better shot?† Want more flexibility from your rifle or handgun? Making your own bullets by casting is an excellent way to gain all these advantages and more. Producing custom-made bullets for your rifle is easy and requires only a modest investment in equipment.

Cast bullets can turn a shoulder-bruising big game rifle into an accurate, well-mannered gun thatís a pleasure to shoot at targets or lighter game.† Frequent practice makes you a better shot and a better hunter, and cast bullets eliminate the factors that mitigate against it, such as expense, wear-and-tear on equipment, and the discomfort of shooting large-caliber rifles.†

Cast bullets can turn a shoulder-bruising big game rifle into an accurate, well-mannered gun thatís a pleasure to shoot at targets or lighter game.† Frequent practice makes you a better shot and a better hunter, and cast bullets eliminate the factors that mitigate against it, such as expense, wear-and-tear on equipment, and the discomfort of shooting large-caliber rifles.†

Many fine old rifles are now gathering dust as mere decorations, but the recent rise of interest in historic weapons has led to the re-introduction of old bullet designs.† Cast bullets are the best way—sometimes the only way—to get guns chambered in obsolete or hard-to-get calibers off the wall and shooting again.

ADVANTAGES OF CAST BULLETS

Jacketed bullets are expensive.† It makes little sense to shoot a high-priced bullet in casual practice, for initial sight-in, or when the game hunted doesn't require it.† The price of cast bullets is a fraction of† that of jacketed ones, and sometimes a cast bullet costs nothing but a little time.† Using cast bullets, especially in handguns, is a real money-saving option.

I once calculated that I can shoot a .45 caliber handgun for almost as little as a .22, thanks to cast bullets. As of this writing (June 2007) Midway USA is selling .45 Colt "Cowboy" loads for about $24-29 per box of 50 depending on brand and bullet type. I can easily duplicate those loads in all respects for about $4.00 per box, not including the initial cost of the brass. Brass cases used with mild loads and cast bullets last a long time: I have one box that has been reloaded seven times, and is easily good for three more, using cast bullets. Thus the cost of the brass is amortized over time.

The most expensive item in a cartridge is the primer. Handgun powder charges are small, and a pound of powder provides anywhere from 1200-1400 shots for about $20: call it about a penny for the powder. Primer prices are rising but they can still be had for less than 3 cents each; at 4 cents per shot the .45 is cheaper to shoot than a .22 WMR or a .17 HMR, and almost the same price as some brands of .22 Long Rifle!

The initial amount I spent for the box of .45 factory loads, after seven reloadings, has long since been paid back. Seven boxes of reloads (350 rounds) at 4 cents per shot cost $14.00; seven boxes of commercial ammunition at Midway's current price would have been $168-203!!

Besides their low cost, cast bullets are very easy on gun barrels, with nowhere near the erosive effect of jacketed ones. It's nearly impossible to wear out a bore using cast bullets, a real bonus if you're worried that extensive practice may result in lost accuracy due to wear. It's also a consideration if you're bringing an old wall hanger back into service. Many old firearms have barrels of fairly soft steel, that were never designed for jacketed bullets at all. They will suffer far more rapid wear from jacketed bullets than from cast ones, even with light loads. A pre-war Colt Single Action Army isn't going to be happy if you shoot jacketed bullets designed for a Model 1911 through it; nor will your great-grandfather's .38-55 like bullets designed for a .358 WinMag. If you've got a gun with significant historic or sentimental interest, cast bullets are the way to make it useful again without damaging it.

Sometimes casting is the only way to get a bullet that works. Some goofball calibers use bullets of an non-standard diameter or have some other oddities about them. I once revived a Swiss Vetterli rifle and was unable to find a suitable commercial bullet: casting was my only real option to make that rifle shoot at all.

Carefully made cast bullets are as accurate as, and sometimes more accurate than, premium-quality jacketed bullets.† Because production is under the complete control of the shooter, not only is any level of "quality control" desired attainable, modifications to the bullet can be introduced to get the most from a particular rifle.† Many target shooters use cast bullets precisely for these reasons.†

Nor are cast bullets to be sneezed at when it comes to hunting: they can be used on virtually anything from varmints to moose.† A .458 Winchester or .450 Marlin with full-house factory loads is grossly overpowered for thin-skinned game like a whitetail, but cast bullets can be loaded into the same cases to provide ample power for medium game without tooth-rattling recoil.

STARTING UP: WHAT DO YOU NEED?

Casting requires some equipment, but good bullets can be made with a minimum of kit and without spending much money.†Some stuff you have to buy, some you can scrounge at home or from the nearest thrift shop.

At a minimum, you will need: 1) a reliable heat source; 2) a pot to melt your lead; 3) a ladle to pour it with; and of course 4) a mold.† Add to this a couple of old stainless steel spoon, a worn-out bath towel, and a short piece of hardwood, and you're ready to start.† The total investment, assuming you buy everything new, need be no more than $75-100, far less if you buy used gear. With jacketed bullets costing anywhere from 12 to 25 cents each, you'll recoup the cost of set-up in the first few hundred rounds.

Now...I am going to put in here a shameless plug for the products made by Lee Precision.  This company makes quality products at very reasonable prices, and over the years I've found myself buying more and more things from them because their stuff just plain works and it doesn't cost an arm and a leg. When it comes to casting equipment, Lee's stuff is the best value on the market. A pretty complete set-up using Lee's casting equipment can cost you less than a single mold from one of the bigger-name makers, and unless you're planning a career as a bullet caster as a commercial venture, Lee's products will serve your needs perfectly.

This company makes quality products at very reasonable prices, and over the years I've found myself buying more and more things from them because their stuff just plain works and it doesn't cost an arm and a leg. When it comes to casting equipment, Lee's stuff is the best value on the market. A pretty complete set-up using Lee's casting equipment can cost you less than a single mold from one of the bigger-name makers, and unless you're planning a career as a bullet caster as a commercial venture, Lee's products will serve your needs perfectly.

They also offer custom services at amazingly low prices. They made me a one-off bullet mold for that Vetterli (double cavity, no less!), exactly to my specifications, for $127, about a third what the other companies charge for this service. They also made me a custom crimping die for the Vetterli rifle and some of the other weird calibers I shoot: Each crimper was less than $30. Custom dies of any type can cost hundreds of dollars from other makers.

And no, they didn't pay me to say this.

MELTING EQUIPMENT

For years I melted lead in a flat-bottomed cast-iron pot on a spare kitchen stove, an electric hot plate, or a small gasoline stove. This works just fine, but using a hot plate or camp stove for melting lead is going to mess it up a bit. Don't do it on your spouse's good kitchen range, though if you've got a spare one in the garage, that works fine.

The flat bottom cast iron lead pots made by Lee and Lyman are very convenient and cheap, but you can substitute any small, deep, stable cast  iron or aluminum pot of the same size. Be sure it has a flat bottom and sits solidly on the stove. Tipping over 10 pounds of molten lead on your feet will not be a happy experience. Using pots for melting lead will ruin them for use with food, don't try to cook in them afterwards!

iron or aluminum pot of the same size. Be sure it has a flat bottom and sits solidly on the stove. Tipping over 10 pounds of molten lead on your feet will not be a happy experience. Using pots for melting lead will ruin them for use with food, don't try to cook in them afterwards!

Some time ago I switched over to an electric melter, simply for the convenience. Electric melters will typically hold 10-20 pounds of metal and have a lever-activated spout to fill the mold. If you go this route, get one with a spout up front, so you can watch the pour, and one with sufficient clearance that the largest mold you have will fit underneath the spout.

I'll be honest and say that I think I cast better bullets using a pot and pouring ladle, but the electric melter has the advantage of better temperature control, as well as the pour spout.

Besides the bullet mold, the only really specialized equipment you need is a small lead ladle, an inexpensive item.† These are essential if you cast from an open pot. If you're using an electric melter with a pour spout the ladle isn't needed.

MOLDS

Molds are the key piece of equipment, and can be expensive. But a mold pays for itself very quickly and will last a very long time. Thereís a plethora of designs on the market for almost any conceivable purpose, but if you have needs that canít be met with something listed in a catalog, you can have a mold made to your specifications for an extra fee.

Molds are the key piece of equipment, and can be expensive. But a mold pays for itself very quickly and will last a very long time. Thereís a plethora of designs on the market for almost any conceivable purpose, but if you have needs that canít be met with something listed in a catalog, you can have a mold made to your specifications for an extra fee.

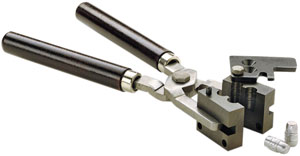

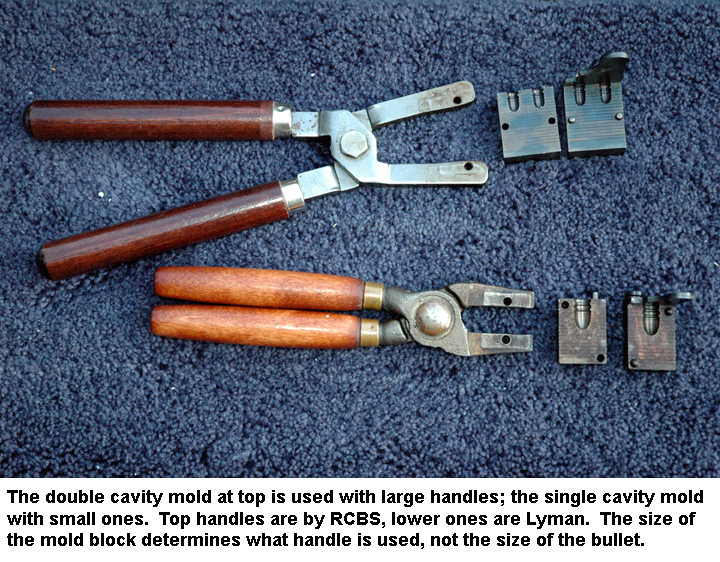

Molds are made by Lee, Lyman, NEI Handtools, RCBS, SAECO and a few smaller companies.† Molds are manufactured from cast iron, hard aluminum, or brass, with the first two being the most commonly encountered.† Cast iron molds are made by Lyman and RCBS; Lee and NEI products are made from aluminum.†

Molds are made by Lee, Lyman, NEI Handtools, RCBS, SAECO and a few smaller companies.† Molds are manufactured from cast iron, hard aluminum, or brass, with the first two being the most commonly encountered.† Cast iron molds are made by Lyman and RCBS; Lee and NEI products are made from aluminum.†

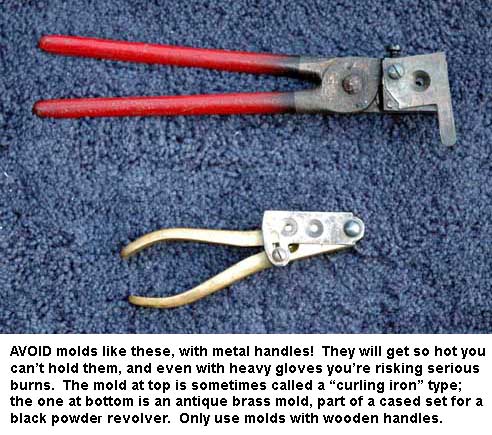

Many long-time bullet casters prefer iron molds, but the fact is that aluminum ones are generally less expensive, faster to come up to casting temperature, less prone to corrosion or rust, and much less fatiguing to use.† They have the added benefit of lower initial cost. Lee molds are the least expensive when bought new, and as a bonus they come already fitted with insulated handles: if you choose other brands you have to buy a set of handles as a separate item.†

Many long-time bullet casters prefer iron molds, but the fact is that aluminum ones are generally less expensive, faster to come up to casting temperature, less prone to corrosion or rust, and much less fatiguing to use.† They have the added benefit of lower initial cost. Lee molds are the least expensive when bought new, and as a bonus they come already fitted with insulated handles: if you choose other brands you have to buy a set of handles as a separate item.†

I've used both iron and aluminum molds by various makers for years, and I'm convinced that aluminum molds produce bullets of equal quality to those cast from iron ones.†Lee molds have worked very well for me; they won't last as long as a Lyman iron mold, but they're about one-third the price of a Lyman, and it would take a long time and a lot of bullets to wear one out.

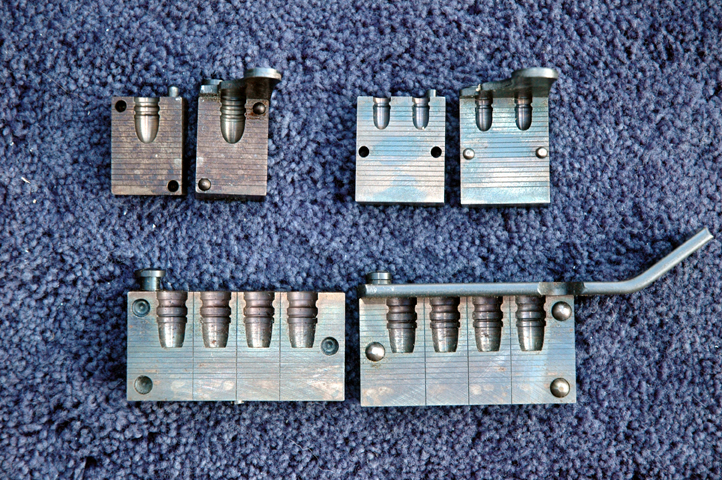

Regardless of manufacturer, molds have anywhere from 1 to 6 cavities, and a swinging plate to cut off the "sprue" that's formed when each cavity is filled.† Few makers produce single cavity molds anymore except for special orders or very large sizes of bullets, but many of them can still be found in the used-equipment market. Four- or six-cavity molds (especially in iron) are heavier than the single-cavity ones, but allow you to produce large numbers of bullets in a short time. A six-cavity mold is really intended for commercial producers and they're pretty pricey.

Regardless of manufacturer, molds have anywhere from 1 to 6 cavities, and a swinging plate to cut off the "sprue" that's formed when each cavity is filled.† Few makers produce single cavity molds anymore except for special orders or very large sizes of bullets, but many of them can still be found in the used-equipment market. Four- or six-cavity molds (especially in iron) are heavier than the single-cavity ones, but allow you to produce large numbers of bullets in a short time. A six-cavity mold is really intended for commercial producers and they're pretty pricey.

Two-cavity molds are a good compromise between speed of casting and fatigue; a 2-cavity mold will easily produce 100 bullets per hour once it's up to temperature. Be aware that mold handles come in two sizes: the large size will fit most 2-cavity to 4-cavity molds but won't fit the older single-cavity molds. If you're using both single and multiple-cavity molds you'll need both. The really big six-cavity molds usually come with handles, but sometimes not. My experience has been that Lyman handles will also fit molds made by RCBS, NEI and SAECO so long as they're the correct size.

Consider buying used molds from Internet auction sites. A lot of really good deals turn up on GunAuction.com, and E-Bay. Used molds vary from extremely used to new-in-box, still wrapped in the original paper. The unused molds are almost always "new old stock" from some store that has closed, or perhaps unsold old inventory. Prices for good molds, even for ones that have never been used at all, rarely will exceed half that of the equivalent new product, and if you want to buy molds by some maker other than Lee, check the auction sites first. Most molds sold through these sites will be older designs no longer in production.†This isn't a handicap: a lot of really fine designs have been discontinued by mold makers due to lack of sales, so if you absolutely have to have a design that's been discontinued for decades...check the auction sites. Sooner or later it will show up. Half of my molds, at least, came from Internet auction sites and I have never been disappointed with one. Most were great bargains, "name brand" products at minimal prices. I've bought several molds this way at fire-sale prices, and it's well worth checking periodically if you want something unusual and especially for "vintage" mold designs. Here's a tip: when searching auction sites be sure to use the spelling mould as well as mold to avoid missing some.† Buying used when it comes to Lee molds is not worth the trouble because the price of a brand-new one is so low. I always get new ones when I'm looking at Lee products. But when it comes to molds from RCBS, Lyman, or NEI, I always look first for a decent used one.†

Consider buying used molds from Internet auction sites. A lot of really good deals turn up on GunAuction.com, and E-Bay. Used molds vary from extremely used to new-in-box, still wrapped in the original paper. The unused molds are almost always "new old stock" from some store that has closed, or perhaps unsold old inventory. Prices for good molds, even for ones that have never been used at all, rarely will exceed half that of the equivalent new product, and if you want to buy molds by some maker other than Lee, check the auction sites first. Most molds sold through these sites will be older designs no longer in production.†This isn't a handicap: a lot of really fine designs have been discontinued by mold makers due to lack of sales, so if you absolutely have to have a design that's been discontinued for decades...check the auction sites. Sooner or later it will show up. Half of my molds, at least, came from Internet auction sites and I have never been disappointed with one. Most were great bargains, "name brand" products at minimal prices. I've bought several molds this way at fire-sale prices, and it's well worth checking periodically if you want something unusual and especially for "vintage" mold designs. Here's a tip: when searching auction sites be sure to use the spelling mould as well as mold to avoid missing some.† Buying used when it comes to Lee molds is not worth the trouble because the price of a brand-new one is so low. I always get new ones when I'm looking at Lee products. But when it comes to molds from RCBS, Lyman, or NEI, I always look first for a decent used one.†

Gun shows are another good source for used molds and other stuff: lots of barely-used equipment will be offered at gun shows. A gun show is an especially good place to look for the more expensive items such as lubricator/sizer presses, if you want to upgrade your capabilities.

ODDS AND ENDS

In addition to the molds and the melting equipment, a few other small items make your life a lot easier. Chief among these is a couple of old stainless steel spoons and a pair of surgeon's/fisherman's forceps. Bullets and sprues are quite hot enough to give you a nasty burn for some time after being dropped from the mold, so you need something to handle them with.

The forceps are for picking up sprues and putting them back in the pot (gently); moving bullets around individually; and for picking out copper jackets. wheelweight clips and other large chunks of debris that float to the top of the melt. The spoons allow you to skim off the small junk from the melt, and later to move the bullets around on the old towel you drop them onto. They also aid in sorting out the wrinkled and not-so-good-looking ones and in counting your production. Keep at least two spoons handy so one can cool off while the other is in use. Don't use your spouse's flatware, buy a couple of junkers at the thrift shop; and use stainless steel only, not silver or silver plate. Lead won't stick to stainless steel.

As I skim and clean my melt I throw the hot dross into a clay dish, the kind of thing you put under a flower pot. Totally heat resistant, cheap, and if you break it, no big deal to replace from any garden center.

SIZING CAST BULLETS

Because of the vagaries of alloys and machining tolerances, most bullets as they fall from the mold are not quite the advertised nominal size.† And sometimes they aren't perfectly round, either, though they should be. (I once bought a VERY expensive set of custom mold blocks for an 8mm rifle, from a manufacturer with a great reputation for quality products, though I won't name the company here. One of the two cavities made bullets that were oval instead of round, visibly eccentric. Since it was a custom order I couldn't return it! That mold is no longer in my collection, needless to say.) Furthermore, cast bullets also need lubrication. The lubricant reduces bore leading and helps maintain normal chamber pressures.

Bullets typically come out of the mold a bit oversized (exactly how much they vary from their nominal diameter depends in some degree on the alloy from which they're cast). Oversized is not generally a problem. A bullet as much as 0.003” over nominal diameter is perfectly safe to shoot in most cases. Not only is there no harm, such a bullet usually effects a better gas seal, and often shoots better than the “correct” size bullet. With jacketed bullets oversized projectiles will greatly elevate breech pressure and increase barrel wear, but the softer cast bullets don't have these effects.

Bullets typically come out of the mold a bit oversized (exactly how much they vary from their nominal diameter depends in some degree on the alloy from which they're cast). Oversized is not generally a problem. A bullet as much as 0.003” over nominal diameter is perfectly safe to shoot in most cases. Not only is there no harm, such a bullet usually effects a better gas seal, and often shoots better than the “correct” size bullet. With jacketed bullets oversized projectiles will greatly elevate breech pressure and increase barrel wear, but the softer cast bullets don't have these effects.

If a bullet is oversized or out of round, "sizing" it to bring it to proper diameter and shape is in order. Sizing is the process of passing the bullet through a perfectly concentric die of exactly the right size, to assure uniformity.† It can often be avoided by judicious choice of mold, and accepting a slightly oversized bullet for the reasons stated above.

If you do find that you have to size your bullets, you need some specialized equipment. A "lubri-sizer" is a machine that does this and simultaneously lubricates the bullet (more about lubrication below). The best one on the market is Lyman's: the current Model 4500 is derived from the older #45 and #450, a very fine product indeed. I have an elderly #45 somewhere, and for the past decade have used a #450. Other companies make similar equipment, such as the RCBS "Lubamatic" at left. Lubrisizers aren't cheap. But if you reload many different calibers, as I do, you may find one to be essential. If you're only loading one or two calibers with cast bullets, and can't use bullets as-cast, Lee again comes to the rescue with an inexpensive sizer that will mount in your loading press (right).

If you do find that you have to size your bullets, you need some specialized equipment. A "lubri-sizer" is a machine that does this and simultaneously lubricates the bullet (more about lubrication below). The best one on the market is Lyman's: the current Model 4500 is derived from the older #45 and #450, a very fine product indeed. I have an elderly #45 somewhere, and for the past decade have used a #450. Other companies make similar equipment, such as the RCBS "Lubamatic" at left. Lubrisizers aren't cheap. But if you reload many different calibers, as I do, you may find one to be essential. If you're only loading one or two calibers with cast bullets, and can't use bullets as-cast, Lee again comes to the rescue with an inexpensive sizer that will mount in your loading press (right).

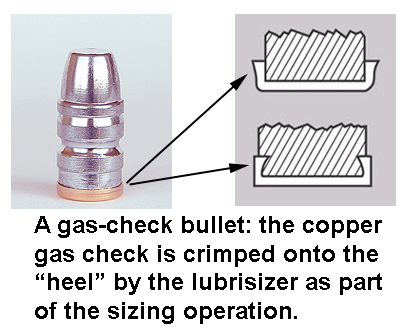

GAS CHECKS

In rifles cast bullets are best used at moderate muzzle velocities.† Overly high velocities can cause lead to melt from friction, with gas leakage past the bullet producing significant fouling and leading of the bore. At 1500 fps or more, itís advisable to use a gas check to reduce or eliminate this problem.† The gas check is a small copper disc crimped onto the base of the bullet. In this case you must run the bullet through a sizer die, which serves also as a gas-check crimper. Using gas checks will allow you to safely drive bullets at 1700-1800 fps, and still avoid leading. Proper choice of alloys and use of lubricants also will minimize this potential issue.

In rifles cast bullets are best used at moderate muzzle velocities.† Overly high velocities can cause lead to melt from friction, with gas leakage past the bullet producing significant fouling and leading of the bore. At 1500 fps or more, itís advisable to use a gas check to reduce or eliminate this problem.† The gas check is a small copper disc crimped onto the base of the bullet. In this case you must run the bullet through a sizer die, which serves also as a gas-check crimper. Using gas checks will allow you to safely drive bullets at 1700-1800 fps, and still avoid leading. Proper choice of alloys and use of lubricants also will minimize this potential issue.

†LUBRICATION AND LUBRICANTS

Proper lubrication reduces or eliminates leading at reasonable velocities and greatly reduces chamber pressures.† All cast bullet designs have circumferential grooves into which lubricant can be forced under pressure: lubrisizers are the best way to do this but it can done by hand, using a waxy stick-type lubricant, filling the grooves with your fingers.† It works but it's messy and slow.

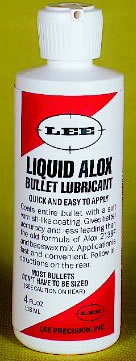

If you're really interested in cutting costs and minimizing the steps you take, look for a mold that throws "tumble lube" bullets. These are designed with a series of very narrow grooves rather than a few larger ones. They don't need sizing or gas checking and can be lubricated as they come from the mold, eliminating a step: "TL" bullets get just a thin coating of lubricant on them applied as a liquid and allowed to dry. The result is similar to the "external lubrication" of a .22 Long Rifle bullet.

If you're really interested in cutting costs and minimizing the steps you take, look for a mold that throws "tumble lube" bullets. These are designed with a series of very narrow grooves rather than a few larger ones. They don't need sizing or gas checking and can be lubricated as they come from the mold, eliminating a step: "TL" bullets get just a thin coating of lubricant on them applied as a liquid and allowed to dry. The result is similar to the "external lubrication" of a .22 Long Rifle bullet.

Lee makes many "TL" molds, plus the lubricant "Liquid Alox" which is an absolute Godsend to the weekend bullet caster.† All that's required is to dribble some of it on the bullets, swish them around in a cup, and then when they're uniformly coated set them on a sheet of paper to dry.† Simple, easy, and very effective.† The entire bullet surface is covered, and the grooves are filled. Once the lube is dried it's pretty resistant to being wiped off, and this method is very effective, especially in handgun calibers because velocities are usually pretty low.

Lee makes many "TL" molds, plus the lubricant "Liquid Alox" which is an absolute Godsend to the weekend bullet caster.† All that's required is to dribble some of it on the bullets, swish them around in a cup, and then when they're uniformly coated set them on a sheet of paper to dry.† Simple, easy, and very effective.† The entire bullet surface is covered, and the grooves are filled. Once the lube is dried it's pretty resistant to being wiped off, and this method is very effective, especially in handgun calibers because velocities are usually pretty low.

LEAD & LEAD ALLOYS

Lead is certainly the most re-cycled metal on the planet.† It's also one of the most common, and obtaining suitable lead for making your own bullets is easy.† One excellent source is the backstop at your club's pistol range.† It's amazing how many bullets can be found lying out on the ground in the open on a typical mounded-earth backstop. Especially after a heavy rain, it's possible to pick up several pounds of expended bullets in a few minutes.† Range scrap is high-quality lead, usually with a little hardening antimony alloyed with it, and makes excellent rifle bullets.† The drawback to it is that it's really dirty stuff. The copper jackets, small rocks, dirt, and other debris have to be skimmed out when they float to the top of the melt.† But an active range is an almost inexhaustible source of free metal. And you can think of it as "cleaning up the environment," so it's really a public service. I'm sure even Al Gore would approve.

Many other sources of lead exist since it's so common in modern society.† Scrap metal dealers can sell you lead cable sheathing, pure-lead plumbing scrap from old houses, sheet lead, and perhaps recycled automotive battery terminals and plates, all of which are essentially pure lead.†

Many other sources of lead exist since it's so common in modern society.† Scrap metal dealers can sell you lead cable sheathing, pure-lead plumbing scrap from old houses, sheet lead, and perhaps recycled automotive battery terminals and plates, all of which are essentially pure lead.†

Another possible source is tire shops.† Older wheel weights were made of lead (newer ones aren't) and sometimes tire dealers will have a barrel or two lying around. Wheel weights aren't the best source of lead but they're cheap, and used judiciously will produce good bullets.† Older lead weights are being phased out (one state has outlawed them entirely) and this source is drying up.

Unfortunately it's getting harder to find lead scrap. The price of all scrap metal is climbing and shops that used to throw it away now find it profitable to sell it. You'll also find that you're competing with people casting fishing weights and other items for local sources. Some scrap dealers won't sell you much less than a ton at a time.

And there are a few scrap dealers who won't sell lead to an individual at all, in any amount. These are the ones who are paranoid that it might be used to cast a bullet that killed someone and they'd get sued. This has never happened in the entire history of the world but there's no accounting for paranoia.

Pure lead is soft and best suited for muzzle-loading bullets (especially hollow-based ones like "Minie balls") and shotgun slugs. Most centerfire guns shoot better with bullets made with a hardening agent added to them.† Antimony or tin are commonly used for this purpose: casters will often add bar solder to the melt get the tin component.†Again, thanks to environmental paranoids and their war on lead (see below) it's almost impossible to find solder with lead in it any more, and I've stopped trying. Pure lead is available at places that supply the plumbing trade and it currently is running about $1-1.50 per pound. That's not too bad (a pound of lead will make 30 230-grain bullets, about 5 cents each) but give me range scrap, every time, as a more cost-effective source.

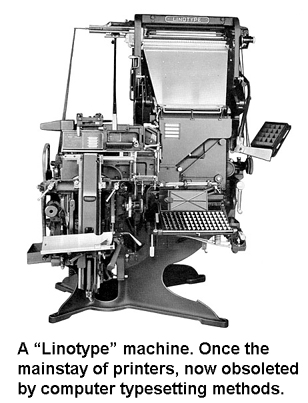

A wonderful source of hard lead alloy that made first-rate bullets used to be printing shops and newspapers: before the days of word processors, "Linotype" machines were sort of hybrids of typewriters and lead smelters, used to cast type slugs (i.e., lines of type, hence the trade name) for printing. They used a special alloy that flowed freely and made excellent bullets.† The Linotype machine has long since been obsoleted by computer printing and typesetting software. Like other dinosaurs, these cranky, smoky, and dangerous contraptions are consigned to museums nowadays, but...you find ingots of this material at a scrap dealer, or even old type slugs, grab them. It’s the best raw material for bullets.

A wonderful source of hard lead alloy that made first-rate bullets used to be printing shops and newspapers: before the days of word processors, "Linotype" machines were sort of hybrids of typewriters and lead smelters, used to cast type slugs (i.e., lines of type, hence the trade name) for printing. They used a special alloy that flowed freely and made excellent bullets.† The Linotype machine has long since been obsoleted by computer printing and typesetting software. Like other dinosaurs, these cranky, smoky, and dangerous contraptions are consigned to museums nowadays, but...you find ingots of this material at a scrap dealer, or even old type slugs, grab them. It’s the best raw material for bullets.

Lead hardness testers are available, but unless you're very fussy, the exact composition of the bullets is really not all that important.† My practice has always quite literally been the "rule of thumb": if I can nick the metal with my thumbnail, it's lead.† If I can nick it easily it's pure lead and I cast muzzle-loading bullets from it.† If it takes some more effort to nick it, it's a hardened alloy.† In either case, if it casts well and the bullets are of uniform weight after cooling, I shoot them and don't worry about what's in them.

Lead hardness testers are available, but unless you're very fussy, the exact composition of the bullets is really not all that important.† My practice has always quite literally been the "rule of thumb": if I can nick the metal with my thumbnail, it's lead.† If I can nick it easily it's pure lead and I cast muzzle-loading bullets from it.† If it takes some more effort to nick it, it's a hardened alloy.† In either case, if it casts well and the bullets are of uniform weight after cooling, I shoot them and don't worry about what's in them.

SAFETY CONSIDERATIONS

Lead is unfortunately poisonous and has to be handled with some respect.† Casting should be done in a well-ventilated place, if possible outdoors (here the gasoline stove has a real advantage over other heat sources) to prevent inhaling lead fumes.†

Melting lead scrap is a smelly business, too, not likely to endear you to your spouse if you do it in the kitchen. Range scrap isn't Chanel No. 5, but wheelweights really, really stink when melted: I think the rubber film and oil and road goo on them is what makes them smell so awful. Melting lead in the kitchen isnít such a good idea anyway, since lead can contaminate food.

Melting lead scrap is a smelly business, too, not likely to endear you to your spouse if you do it in the kitchen. Range scrap isn't Chanel No. 5, but wheelweights really, really stink when melted: I think the rubber film and oil and road goo on them is what makes them smell so awful. Melting lead in the kitchen isnít such a good idea anyway, since lead can contaminate food.

Molten lead has a temperature of well over six hundred degrees Fahrenheit, and splashing it on your skin or getting it in your eye isn't a happy thought.† Wear long sleeved shirts and gloves, and above all use eye  protection.† Safety goggles or, better, a full-face shield are cheap insurance for your vision.† Be careful not to get water into molten lead, as the explosive steam it produces will cause spattering. A live primer that gets mixed into your scrap will really ruin your afternoon, too.

protection.† Safety goggles or, better, a full-face shield are cheap insurance for your vision.† Be careful not to get water into molten lead, as the explosive steam it produces will cause spattering. A live primer that gets mixed into your scrap will really ruin your afternoon, too.

One word of caution: if you collect range scrap you may be inclined to clean it by washing off the dirt before melting. If you do this (I don't) be  absolutely SURE that the stuff is completely dry when it's ready to go into the pot. It's a good idea to let any rinsed scrap lie out in the sun to dry for several days to a week, and let it get good and warm, to be sure it's dry.

absolutely SURE that the stuff is completely dry when it's ready to go into the pot. It's a good idea to let any rinsed scrap lie out in the sun to dry for several days to a week, and let it get good and warm, to be sure it's dry.

A good manual is also worth the small amount it costs, as it will provide many useful hints and tips.† Lymanís Cast Bullet Handbook is the standard against which others are measured; another fine work is Cast Bullets by Colonel E.H. Harrison, published by the National Rifle Association of America.† A few bits of gear, a couple of reference manuals, and some of your time are all you need to become a bullet caster.

A good manual is also worth the small amount it costs, as it will provide many useful hints and tips.† Lymanís Cast Bullet Handbook is the standard against which others are measured; another fine work is Cast Bullets by Colonel E.H. Harrison, published by the National Rifle Association of America.† A few bits of gear, a couple of reference manuals, and some of your time are all you need to become a bullet caster.

ONE MORE REASON TO CAST YOUR OWN

Here's something to be kept in mind: these are perilous times for shooters. Our enemies have made gains in recent years. Being able to make ammunition on your own renders you independent of external sources of supply, and that's no small advantage.

Here's something to be kept in mind: these are perilous times for shooters. Our enemies have made gains in recent years. Being able to make ammunition on your own renders you independent of external sources of supply, and that's no small advantage.

Today there may be no special licenses needed to buy equipment or make ammunition for your own use: but don't count on that being true forever. Frustrated by their inability to ban guns, the anti-gun crowd is now turning its attention to ammunition: in recent years there have been many attempts to limit the kind and amount of ammunition individuals can own.

Already, in several states you may not buy handgun ammunition without a handgun license. In some you may not buy ANY ammunition without a "Firearm Owner's Identification Card." The Forces Of Darkness are not ignorant about reloading: it is already the case in some places that you must have permits to buy black or smokeless powder. Some states and cities prohibit possession of any ammunition if you don't have a license for a gun in that caliber. The Department of Homeland Security tried very hard to include reloading supplies in the revamped BATFE statutes, and the Virginia Tech shootings led the Governor of Virginia to call for limits on how much ammunition you can buy or possess. This is real, folks: the Black Hats mean business and they will use any means to get what they want.

Infringements aren't always imposed by statute: often they are enforced by regulation. Through increasingly stringent state and local storage requirements, tighter controls on inter- and intra-state shipments of loaded ammunition, zoning limits on how much ammunition can be held in stock in a store, special licensing requirements for retailers of ammunition, bans on mail-order sales, bans on lead objects smaller than a minimum size—all of which, and more, have been tried and in some cases written into law or commercial codes—they hope to harass and intimidate gun shops and sporting goods stores into dropping as many lines of ammunition products as possible. The Richmond, Virginia Fire Marshall (enthusiastically supported by the BATFE) has used "safety regulations" to limit how much smokeless gunpowder can be in a shop or on display at a gun show. Some insurance companies are beginning to cancel homeowner policies if they find out you have "explosives" in the house.

Infringements aren't always imposed by statute: often they are enforced by regulation. Through increasingly stringent state and local storage requirements, tighter controls on inter- and intra-state shipments of loaded ammunition, zoning limits on how much ammunition can be held in stock in a store, special licensing requirements for retailers of ammunition, bans on mail-order sales, bans on lead objects smaller than a minimum size—all of which, and more, have been tried and in some cases written into law or commercial codes—they hope to harass and intimidate gun shops and sporting goods stores into dropping as many lines of ammunition products as possible. The Richmond, Virginia Fire Marshall (enthusiastically supported by the BATFE) has used "safety regulations" to limit how much smokeless gunpowder can be in a shop or on display at a gun show. Some insurance companies are beginning to cancel homeowner policies if they find out you have "explosives" in the house.

There is an on-going war on lead, as well. The first victory, the ban on lead shot for waterfowl, came in the late 1980's and it's been gathering momentum ever since. Serious proposals have been put forward at state and federal levels to ban the use of ALL lead projectiles, including those from rifled weapons, using the argument that lead fragments in gut piles adversely affect scavenging birds!

The Clinton Administration EPA tried very, very hard for a backdoor ban on bullet casting, by proposing a rule to ban the "...home casting of lead objects smaller than one inch in any dimension." This was ostensibly to "protect the environment" from the "danger" posed by lead fishing weights; but the real target of the proposal was pretty obvious.

The war on lead is serious, and it's being conducted with great zeal by Eco-Nazis operating pretty much under the public radar by masking their efforts as environmental concern, they way they they did when imposing the lead shot ban. It's entirely possible that at some time in the future, it will be far, far more difficult to cast bullets than it is today.

MORAL: Stock up, and get kitted out, NOW. Some day you may need this stuff.

| HUNTING | GUNS | DOGS |

| FISHING & BOATING | TRIP REPORTS | MISCELLANEOUS ESSAYS |

| CONTRIBUTIONS FROM OTHER WRITERS|

| RECIPES |POLITICS |